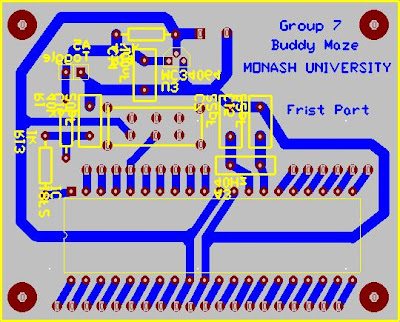

Today is the day to finish my PCB. We have finalized our schematic design therefore I can finish the whole PCB.

The PCB will be a double decker PCB with the top part consist of PIC and the circuit. The bottom part will consist of 2 voltage regulator circuit, 2 switches, motor driver and a pair of motors circuit. We are using 2 battery types that consist of a 9V square DC battery and 5 rechargeable batteries of 1.2V. The 9 Volts battery will be used to drive the electronic circuit and the other for the motors.

For the chases, we are using a plate of aluminum with a thickness of 2 mm. We are using 3 SHARP IR sensors. These sensors will be placed at front, right and left. At the front of the chases will be placed 2 batteries holder with 5 batteries attached to it. Two motors will be attached at the bottom of the chases. A 9 Volts battery will be placed at the back of the bottom chases.

The PCB will be a double decker PCB with the top part consist of PIC and the circuit. The bottom part will consist of 2 voltage regulator circuit, 2 switches, motor driver and a pair of motors circuit. We are using 2 battery types that consist of a 9V square DC battery and 5 rechargeable batteries of 1.2V. The 9 Volts battery will be used to drive the electronic circuit and the other for the motors.

For the chases, we are using a plate of aluminum with a thickness of 2 mm. We are using 3 SHARP IR sensors. These sensors will be placed at front, right and left. At the front of the chases will be placed 2 batteries holder with 5 batteries attached to it. Two motors will be attached at the bottom of the chases. A 9 Volts battery will be placed at the back of the bottom chases.

With all of that, the physical body of the robot is finished and ready to be built. The other problem that is needed to be done is for the programming. Right now we are still learning how to use the compiler and we hope that we will be able to finish the project on time.